Mechanising Zen

Turning mechanical

A gif inspired 3 years of mechanical tinkering.

I spent a few years making an electronically-controlled device that uses 36 motors and 36 identical acrylic tiles to make a kinetic art piece that produces 4096 symmetrical patterns in clustered waves of tile rotation. I love it.

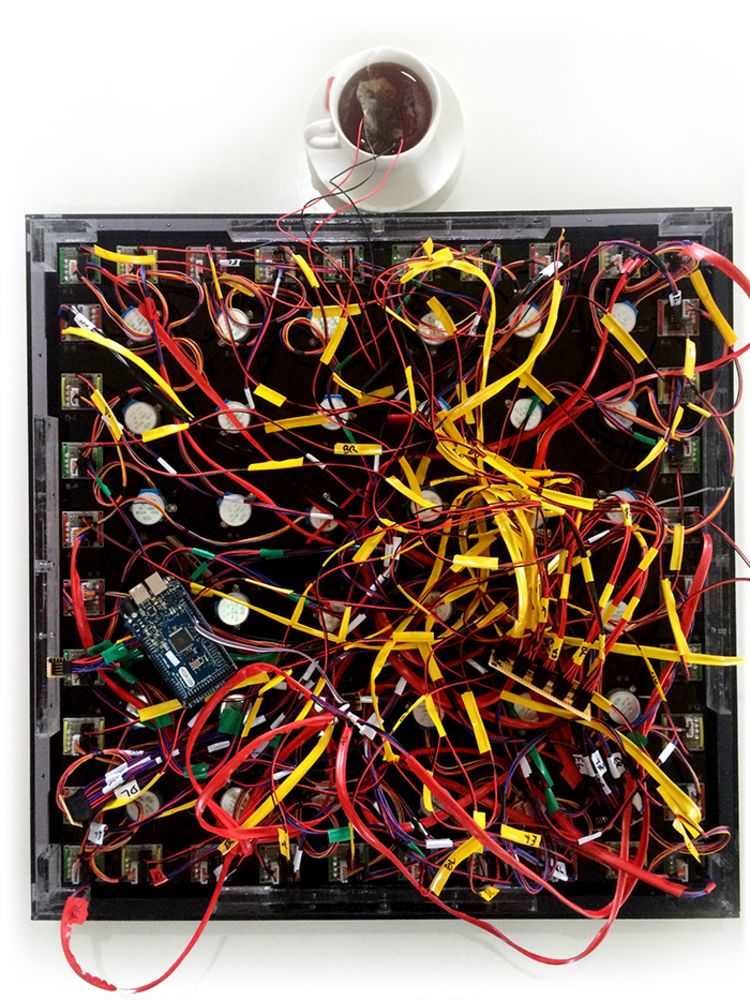

The back of it though looks like it'd only need a nice hot cup of tea before it would turn into an Infinite Improbability Drive.

Along with not being a mechanical engineer , I am clearly also not an electrical engineer (a friend helped A LOT with the Arduino programming and wiring concept. ...not the actual wiring or wiring layout, that mess is my own).

The 36 motors need 36 'drivers'. They are all grouped into 6 clusters, which have their own little power hub, and they are all plugged in to a control board which handles sending each of the clusters timed signals to rotate, and counts the steps or degrees each motor shaft rotates to ensure that the shafts turn 90 degrees.

Then I came across the following animated gif:

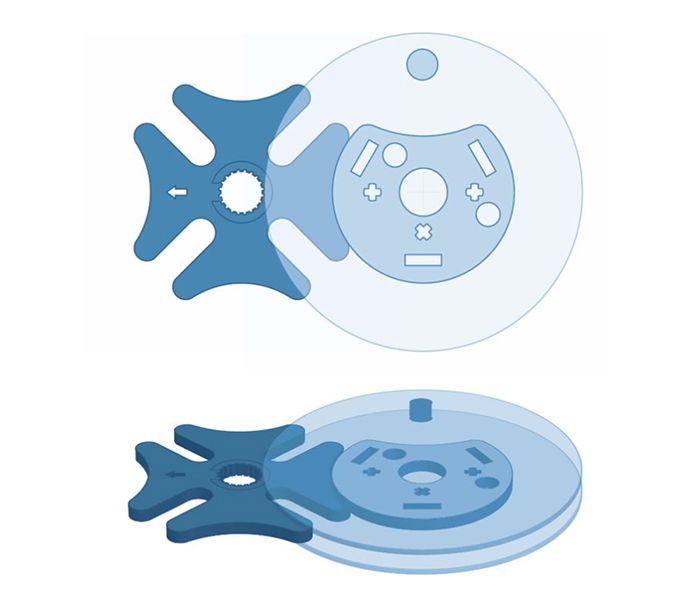

It illustrates a mechanical connection that has been used in devices from film projectors to sorting machines and it's called a "Geneva drive" (or Geneva mechanism, or Geneva gear).

To me, it represented a challenge to replace the 36 motors, control boards and digital programming of the electronic zen board with a single, continuously rotating motor and no control software. A purely mechanical solution.

Of course there'd be a few other components too. If this was all going to be driven by a single motor, the clusters of tiles and the method to keep them synchronised would all need to be mechanically implemented. That means gears.

Lots of gears.

Geneva

Convention

I first wanted to test out the whole 'Geneva gear' thing, so I drew up a prototype and laser-cut some pieces out of 3mm acrylic: a cross and a crescent-shaped disc. A short piece of rod, near to and orbiting the disc, engages with a slot in the cross, rotating it 90 degrees. In my prototypes, the rod is mounted between two clear larger discs attached to the crescent.

All well and good in theory, and my first prototype mostly worked. So I made a bunch and mounted them on a test board with steel bolts as shafts. They hit one another. I made another set with shorter, more rounded crosses. They disengaged from the crescents at times. Another set with shallower crescents. Still not perfect, but reassuring enough to warrant the purchase of 'real' steel shafts and bearings and to build a "full-size" board for working out the rest of this contraption.

Then it was time to work up a plan. Layer by layer.

Tiles are in clusters of either 4 or 8, labelled here as A, B & C (4 tiles each) and D, E & F (8 tiles each). In order that the patterns they produce remain symmetrical, some tiles rotate clockwise, and some anticlockwise, as illustrated by the arrows.

The Geneva drives are what ensures that the tiles all spend the majority of their time NOT rotating, despite the whole mechanism being run from a single continuously turning motor.

There's one drive per tile cluster, and they are positioned such that each of the cross components corresponds to one 'driven' tile per cluster.

The gear box or gear train links each Geneva drive to the motor, and uses gears with different numbers of teeth.

As a result, each Geneva drive rotates at a different rate, meaning that the clusters they control then rotate at a different rate. Sometimes only a single cluster rotates, sometimes two or more clusters rotate at the same time or almost simultaneously, and occasionally all six clusters (all 36 tiles) will rotate at once. Although there's no randomness in the system, to a viewer, the timing seems unpredictable.

Clusters need to have all their tiles connected so that they rotate simultaneously - this is done through gears, one of which per cluster is 'driven' by a Geneva drive.

In the case of Cluster A, the innermost cluster, four gears are directly connected to one another and fixed to the shafts they are mounted on (and to the tiles at the ends of those shafts), meaning that with one of them connected to a Geneva drive, all four rotate together: two clockwise, and two anti-clockwise.

Other clusters are more complicated, requiring that tiles spread over a greater distance need to be connected by free-spinning gears mounted on other shafts ('free-spinning' in that they don't rotate the shafts on which they are mounted). To ensure that the rotation of tiles is in the right order, some of these free-spinning gears need to mesh 'diagonally' across the grid of shafts (which requires a mini-stack of 2 gears to span the larger diagonal distance, while still meshing with the horizontal or vertical chains of gears).

Layer four shows how double-stacks of free-spinning gears are used towards the corners of the grid in order to complete a chain of the eight gears that are fixed to their shafts and will drive tiles at their ends.

Cluster C spans the full perimeter of the grid, despite having to drive just four gears/tiles (one in each corner).

Cluster F (which is fun to say at any time), is unusual in that it is entirely double-stacks of large and small driven gears, layered in such a way that the larger gears mesh at the 'corners', without impeding one another - using smaller gears that mesh on the horizontal and vertical sections of the gear chain.

Finally at the tiles themselves.

These are arranged in a chessboard-like fashion of two layers so that all the tiles that rotate clockwise are on one layer, and all those that rotate anti-clockwise are on another. In this way, the tiles don't run into one another when rotating.

A gearbox

Moving things at different speeds

Tiles on the board are in six clusters.

Each cluster has either four or eight tiles placed symmetrically on the board. Each of the outer corner tiles, for instance, makes a single cluster of four tiles. Similarly, the inner-most four tiles is a cluster.

The clusters don't all rotate at the same time. Sometimes a single cluster rotates, at other times, groups of clusters rotate simultaneously. On the electronic version, this is handled by powering groups of motors together, with each group of motors having different intervals between each time they power.

To achieve something similar with the mechanical version, the idea is to take a single motor continuously rotating and pass that power down a drivetrain of gears of different sizes. The different number of teeth on the gears mean that the train of gears changes in rotational speed the further away from the source. Each cluster of tiles then takes its power from a different place on the drivetrain resulting in each cluster having a different speed. The Geneva gear in each cluster takes the continual motion delivered by the drivetrain and turns it into periodic rotation of 90 degrees for the cluster. Now each cluster will rotate by 90 degrees, then pause etc at a different interval to each other cluster.

But... I wanted to limit the overall number of different parts in the machine and to constrain mechanical complexity. So the drivetrain uses only two differently-sized gears. The gears are sandwiched one on top of another in pairs: one with 26 teeth and one with 25 teeth. The pairs are then arranged in a basic 'line' and alternately flipped so that the 26 tooth gear of one pair meshes with the 25 tooth gear of the next pair etc.

In order to be able to easily distinguish between the 25 tooth gear and the 26 tooth gear, they were made different colours. Laser-cut from acrylic, the gears also feature a coupling device so that they lock together in their pairs. For sufficiently-precise placement of the parts while gluing, they were temporarily held together with short Lego axles, which have the added benefit of not being so easily melted by the solvent used to permanently bond pieces of acrylic together.

Applying invisible hot light to acrylic in order to make the tile mounting plates

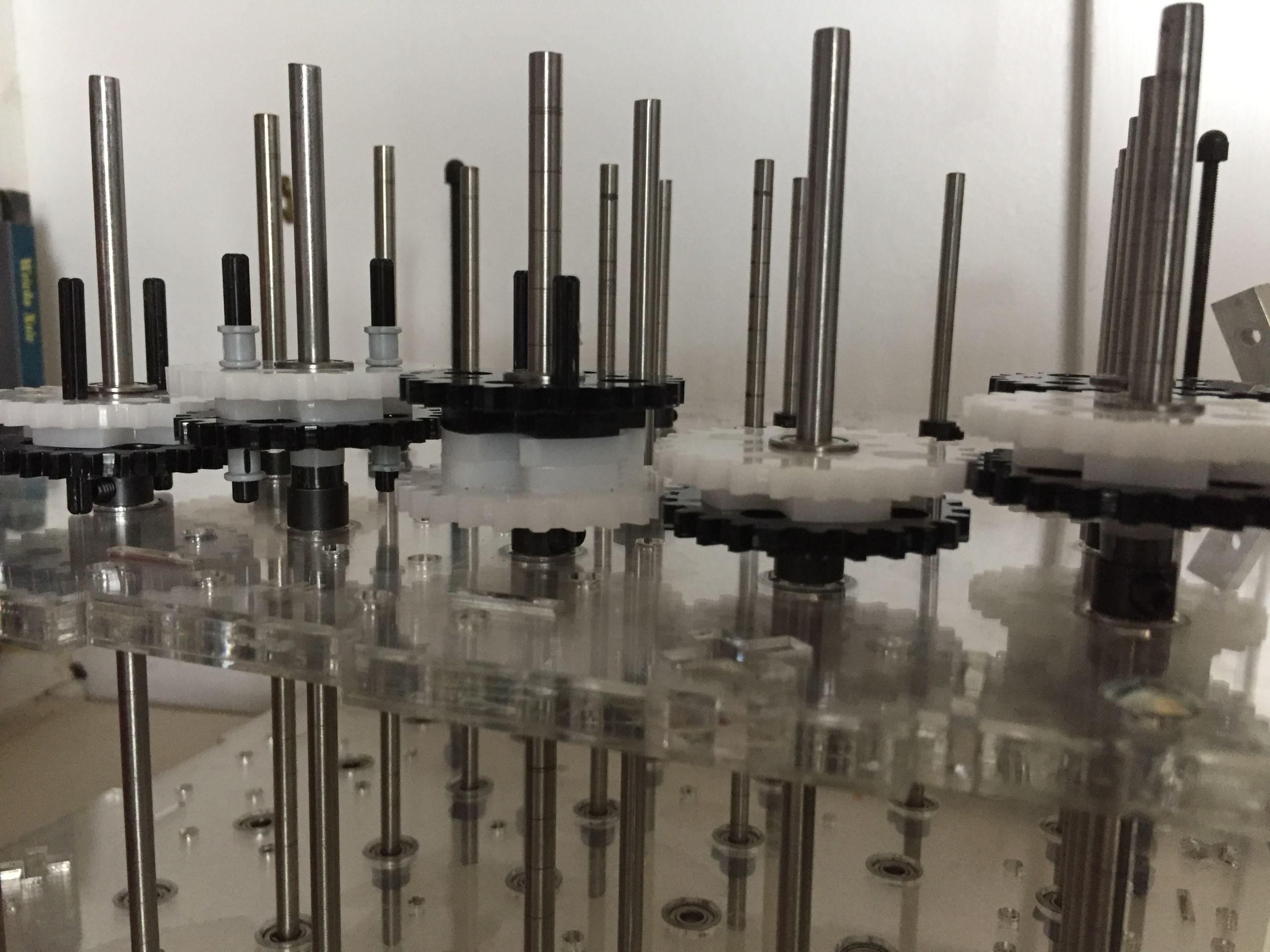

Thirty six steel rods are suspended between 72 bearings mounted in two bearing&acrylic-sheet sandwiches.

As there's only 36 rods, they need to hold all the gears. For added complexity, some of those gears turn the rods, others need to spin freely on the rods in order to deliver rotation to a gear and rod somewhere else on the board, and some are part of the multi-speed gearbox that makes each cluster of tiles rotate at a different speed. ...so some gears are fixed to the rods, and some are mounted on additional bearings.

Still, it all comes together nicely.

A motor attached with a flexible toothed belt to a single one of the Geneva mechanisms sets the thing in motion. ...and ...it works. Slowly, but worky.

I quite like the slow speed. The pattern change is very subtle. But it doesn't make for great video. So here it is at super-speed:

The 'front' - at about 20 x actual speed

At the moment, there's a front and a back. ...though it's built such that both 'sides' will support a full tile-set.

Until I get around to making that second set of tiles, there's also a better opportunity to see what's going on inside.

Watching those gears turn

The 'back' - at about 20 x actual speed

This is a work in progress.

More to come.